In the past few decades, Membrane Bioreactor (MBR) technology has emerged as a wastewater treatment technology of choice over the activated sludge process (ASP), which has been the conventional municipal wastewater technology over the last century.

An MBR is a hybrid of a conventional biological treatment system and physical liquid–solid separation using membrane filtration in one system. MBRs have been used for both municipal and industrial wastewater treatment and reclamation.

Must read: BIOREMEDIATION – TYPES , ADVANTAGES & EXAMPLES

The use of microfiltration membrane bioreactors (MBRs) overcomes many of the limitations of conventional systems. These systems have the advantage of combining a suspended growth biological reactor with solids removal via filtration.

What is Membrane Filtration?

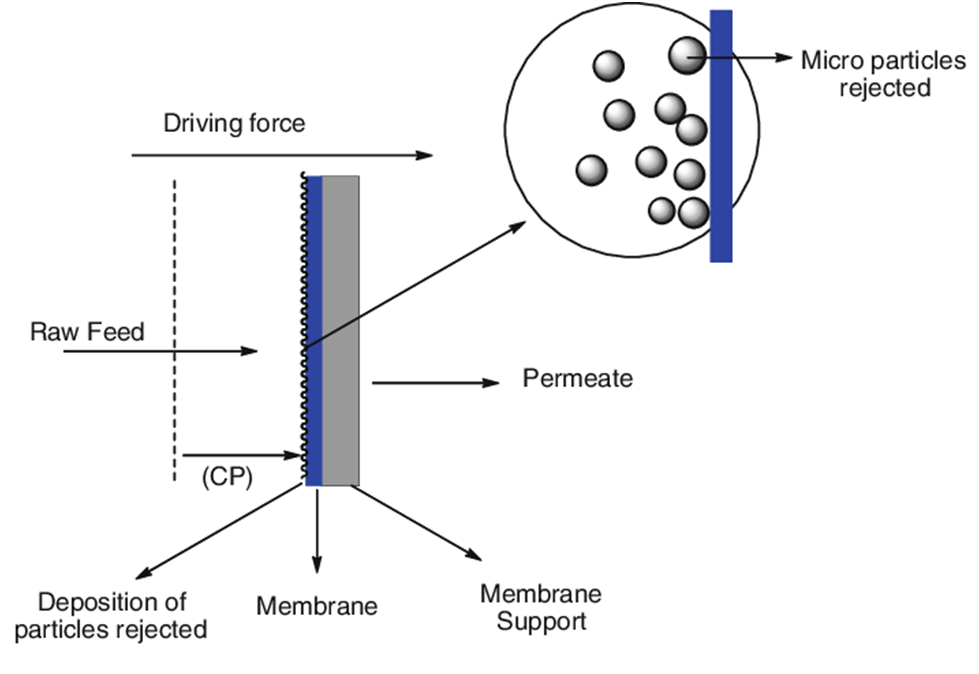

Membrane filtration involves the flow of water containing pollutants across a membrane. Water permeates through the membrane into a separate channel for recovery .

Because of the cross-flow movement of water and the waste constituents, materials left behind do not accumulate at the membrane surface but are carried out of the system for later recovery or disposal. The water passing through the membrane is called the permeate, while the water with the more-concentrated materials is called the concentrate or retentate.

Advantages of Membrane bioreactor (MBR) systems

The MBR technology provides the following advantages over activated sludge process (ASP): High-quality effluent, higher volumetric loading rates, shorter hydraulic retention times (HRT), longer solid retention times (SRT), less sludge production, and potential for simultaneous nitrification/denitrification in long SRTs.

The advantages of MBR systems over conventional biological systems include:

Better effluent quality

The effluent from MBRs contains low concentrations of bacteria, total suspended solids (TSS), biochemical oxygen demand (BOD), nitrogen and phosphorus. This facilitates high-level disinfection. Effluents are readily discharged to surface streams or can be sold for reuse, such as irrigtion.

Smaller space requirements

The inclusion of membranes in the system eliminates the need for secondary clarifiers. The elimination of secondary clarifiers results in significantly reduced plant area requirements.

MBRs operate at higher volumetric loading rates which result in lower hydraulic retention times. The low retention times mean that less space is required compared to a conventional system.

Smaller bioreactors

Membrane filtration allows a higher biomass concentration to be maintained, thereby allowing smaller bioreactors to be used.

Ease of automation

Disadvantages of Membrane bioreactor (MBR) systems

The use of MBR technology has disadvantages like higher energy costs, the need to control membrane fouling problems, and potential high costs of periodic membrane replacement.

Higher capital and operating costs

The primary disadvantage of MBR systems is the typically higher capital and operating costs than conventional systems for the same throughput. O&M costs include membrane cleaning and fouling control, and eventual membrane replacement.

Higher energy costs

Energy costs are also higher because of the need for air scouring to control bacterial growth on the membranes.

Need for chemicals

In addition, the waste sludge from such a system might have a low settling rate, resulting in the need for chemicals to produce biosolids acceptable for disposal.

What is Membrane Fouling?

Membrane fouling remains a major drawback of MBR, as it significantly reduces membrane performances and membrane lifespan, leading to an increase in maintenance and operating costs.

Membrane fouling in MBRs is attributable to suspended particulates (microorganisms and cell debris), colloids, solutes, and sludge flocs. These materials deposit onto the membrane surface and into the membrane pores, clogging the pores, and leading to a decline in the permeability of the membrane.

The membrane bioreactor (MBR) has emerged as an efficient compact technology for municipal and industrial wastewater treatment. However, the heterogeneous nature of suspended solids and active microorganisms in mixed liquor suspended solids (MLSS) makes membrane fouling an inevitable challenge that is difficult to control in long-term MBR applications.

PRACTICE QUESTIONS

QUES . “Membrane Bioreactors” are often discussed in the context of: UPSC PRELIMS 2024

(a) Assisted reproductive technologies

(b) Drug delivery nanotechnologies

(c) Vaccine production technologies

(d) Wastewater treatment technologies

Ans (d)