What is Activated Carbon?

Activated Carbon is a solid, porous, carbonaceous material prepared by carbonizing and activating organic substances.

Activated carbon, also known as activated charcoal, has been commercially used as a purification media since the early 19th century. Today, activated carbon comes in various forms and is used in many drinking water, industrial air and water treatment, businesses, and homes to remove contaminants.

Activated Carbon is a highly porous material that removes organic compounds from liquids and gases by a process known as “adsorption.” Adsorption is where organic molecules in a liquid or gas, are attracted and adhere to the surface of the activated carbon, as the liquid or gas passes through it.

How is Activated Carbon Produced?

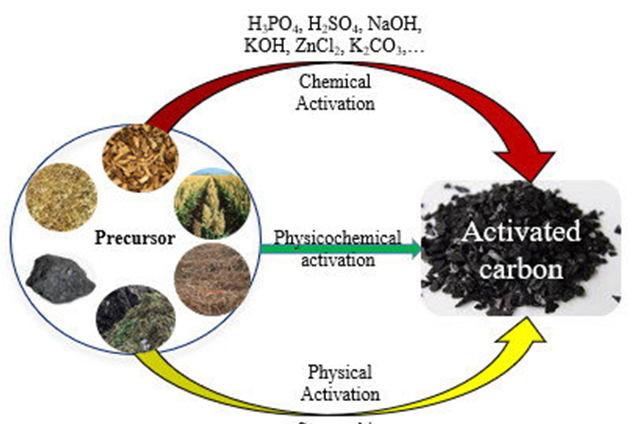

Activated carbon can be made really from any carbon-containing starting material. Activated carbon can be easily synthesized from environmental wastes with high carbon content. Thus, the main requirement for a cost-effective product is that the raw material should have a high carbon content and be easy to source.

The raw materials, which include sawdust, peat, lignite, coal, cellulose residues, coconut shells, petroleum coke, etc., may be carbonized and activated at high temperature with or without the addition of inorganic salts in a stream of activating gases such as steam or carbon dioxide.

Alternatively, carbonaceous matter may be treated with a chemical activating agent such as phosphoric acid or zinc chloride and the mixture carbonized at an elevated temperature, followed by removal of the chemical activating agent by water washing.

What is the Structure of Activated Carbon?

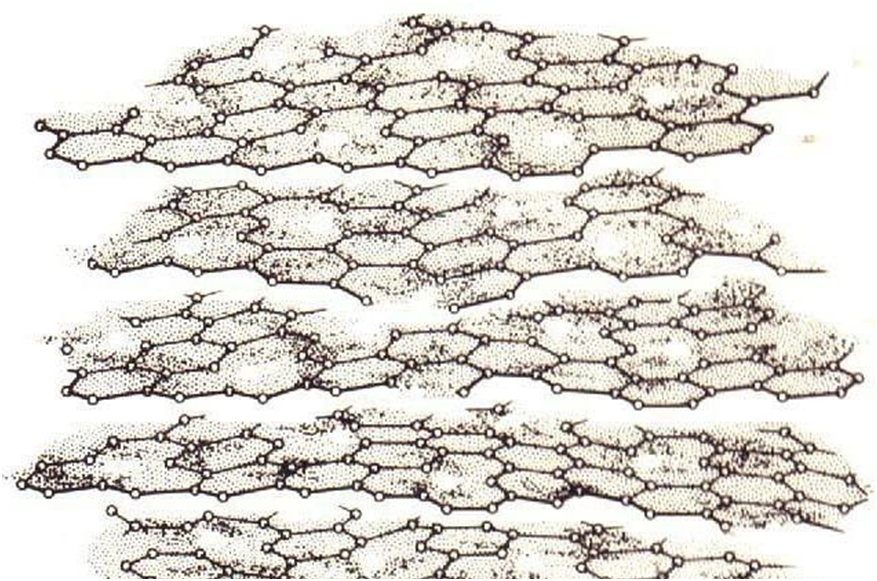

Activated carbon is composed of a random, imperfect structure of graphite platelets and is essentially a crude form of graphite, the material used for pencil leads. This structure resembles a deck of well-used playing cards.

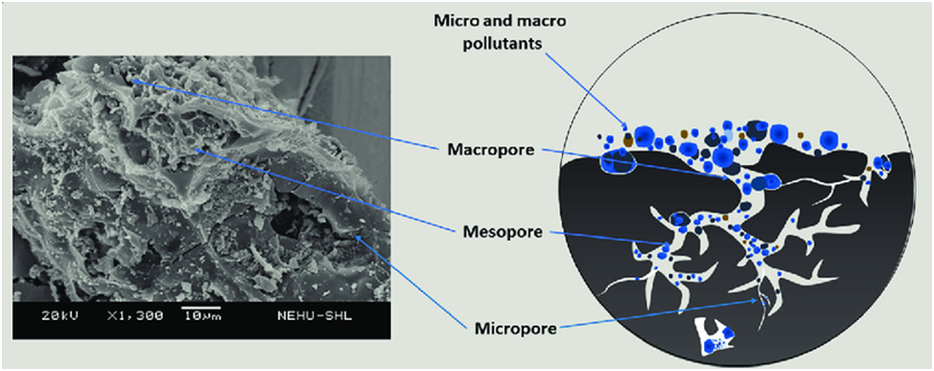

This imperfect arrangement of platelets, connected by carbon-carbon bonds, creates a highly porous structure. This structure has a broad range of pore sizes from visible cracks and crevices down to molecular scale pores.

This graphitic platelet structure gives activated carbon its very high internal surface area. Activated carbon can have a surface area greater than 1000 m²/g. This means that only 5 gm of activated carbon has an internal surface area equivalent to a football field. This surface area enables activated carbon to adsorb various organic compounds from air, gases, and liquids.

Activated carbon exhibits a large surface area and a strong potential for adsorbing heavy metals.

What are the uses of Activated Carbon?

Activated carbon is used in methane and hydrogen storage, air purification, capacitive deionization, supercapacitive swing adsorption, solvent recovery, decaffeination, gold purification, metal extraction, water purification, medicine, sewage treatment, air filters in respirators, filters in compressed air, teeth whitening, production of hydrogen chloride, edible electronics, and many other applications.

Thus, activated carbon is a good and an attractive tool to remove pollutants from effluent streams and to

remediate contaminants from various industries. These multiuse applications make it a versatile form of carbon that is used daily in many industries.

What are the Main Forms of Activated Carbon?

Not all activated carbon is the same and so the selection of the appropriate raw material, product form and properties is critical for each application. Activated carbon or activated charcoal comes in many different forms which are primarily in the form of a granular product, an extruded product or as a powder.

Granular Activated Carbon (GAC)

Granular activated carbon is an irregularly shaped particle crushed from its raw material form and then sized to specific mesh sizes. These sizes typically range from 0.2mm to 5 mm.

The adsorptive capacity of GAC makes it ideal for removing contaminants from water, air, liquids, and gases. Typically, granular activated carbons are placed in a filter bed in a steel or concrete vessel. In water or liquid applications, the liquid typically flows downwards through the carbon filter bed by gravity. For air, vapour or gas processes, the air or gas typically flows upwards through the carbon bed.

When granular carbon can no longer adsorb any more material, it is considered exhausted or spent. This spent granular carbon has the advantage that it can be recycled by thermal reactivation for reuse multiple times and returned to customers for reuse, instead of disposal.

Pellets or Extruded Activated Carbons

Pellets are produced by compressing or extruding the activated carbon into formed cylinders. They generally have diameters ranging from 0.8 mm to 5 mm, with typical sizes of 3 mm and 4mm. They are predominantly produced from coal but also from coconut-based feedstocks.

The production process gives them high mechanical strength, uniformity of shape, and low dust content, making them more appropriate for removing contaminants from air and gas streams.

Pellets are typically used for air and gas purification applications as low-pressure drops tend to be more crucial for these applications. Pelletised carbons operate similarly to granular activated carbons in a carbon filter bed where the air or gas passes through it. Pellets can also be recycled by thermal reactivation for reuse multiple times for the same application.

Powder Activated Carbons (PAC)

Powder activated carbons are produced by pulverising a granular activated carbon feedstock or from fines generated during activated carbon production. Powder carbons have a size predominantly less than 0.045 mm or 45 microns (<325 US Mesh) and they can be produced from any carbon-based feedstock.

The use of powder activated carbons tends to differ from that of granular or pelletised carbons. They are typically applied in batch operations by dosing or added into a water or gas stream and are filtered out later after use. In the liquid phase, this is mostly in batch operations, where the powder dosage can be adjusted to suit the particular requirement.

Activated Carbon Cloth

Activated carbon can also be produced in the form of a cloth or textile which can be in a woven or knitted form. This form of activated carbon has a microporous structure and is 100% activated carbon. Carbon cloth tends to be used in more specialised applications such as in medical or specialised clothing applications.

Impregnated Activated Carbons

Certain compounds have a low adsorption capacity on the base activated carbon. Therefore, to enhance the carbons performance, finely distributed chemical solutions can be selectively added to the carbon surface to generate impregnated activated carbons.

They are typically in pellet or granular form and are predominantly produced from coal and coconut-based feedstocks.

Impregnated carbons are primarily used in air or gas phase applications and usually for the removal of hazardous contaminants. The chemical impregnants that have been incorporated into the carbon can neutralize the adsorbed contaminants through a chemical reaction at its surface.

PRACTICE QUESTIONS

QUES . Consider the following statements: UPSC PRELIMS 2025

Statement I: Activated carbon is a good and an attractive tool to remove pollutants from effluent streams and to remediate contaminants from various industries.

Statement II: Activated carbon exhibits a large surface area and a strong potential for adsorbing heavy metals.

Statement III: Activated carbon can be easily synthesized from environmental wastes with high carbon

content.

Which one of the following is correct in respect of the above statements?

(a) Both statement II and Statement III are correct and both of them explain Statement I

(b) Both Statement II and Statement III are correct but only one of them explains Statement I

(c) Only one of the Statements II and III is correct and that explains Statement I

(d) Neither Statement II nor Statement III is correct.

Answer – (a)