What is Coal Bed Methane (CBM)?

Coal Bed Methane (CBM) is natural gas contained in coal.Coal Bed Methane (CBM) is absorbed into the fissures within un-mined coal seams

CBM – FROM HAZARD TO RESOURCE

Coalbed gas or Coalbed methane, has remained a major hazard affecting safety and productivity in underground coal mines for more than 100 years. Coalbed gas emissions have resulted in outbursts and explosions where ignited by open lights, smoking or improper use of black blasting powder, and machinery operations.

Investigations of coal gas outbursts and explosions during the past century were aimed at predicting and preventing this mine hazard. During this time, gas emissions were diluted with ventilation by airways (e.g., tunnels, vertical and horizontal drillholes, shafts) and by drainage boreholes.

The 1970’s `energy crisis’ led to studies of the feasibility of producing the gas for commercial use. Subsequent research on the origin, accumulation, distribution, availability, and recoverability has been pursued vigorously during the past two decades.

Since the 1970’s research investigations on the causes and effects of coal mine outbursts and gas emissions have led to major advances towards the recovery and development of coalbed methane for commercial use. Thus, coalbed methane as a mining hazard is being harnessed as a conventional gas resource.

What are the characteristics of Coal Bed Methane (CBM)?

• The natural gas found in coal is “sweet” not “sour”, meaning it does not contain hydrogen sulphide.

• It is generally near-pipeline quality when produced and requires minimal processing.

• It is typically produced at lower pressures than conventional natural gas.

Why Coal Bed Methane (CBM) is known as unconventional gas?

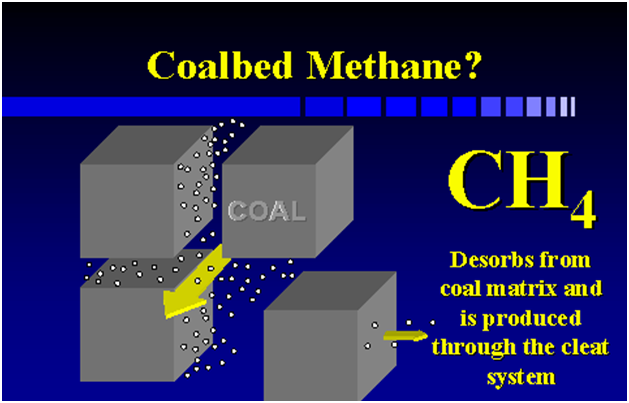

• CBM is called an unconventional gas because the coal acts as both the source of the gas and the storage reservoir.

• Most of the CBM is attached to or “adsorbed” on the coal surfaces and it may also be trapped in the coal fractures, which tend to have low permeability.

• The gas is contained in difficult-to-produce reservoirs, which require special completion, stimulation and/or production techniques to achieve economic production. The coal remains in place after the CBM is removed.

How Coal Bed Methane (CBM) is created?

When plant material such as roots, bark, and wood are deposited in swamps or swampy lakes, they undergo bacterial and chemical changes to make peat deposits. As the peat is buried deeper, under layers of sand and mud, over millions of years, it changes to brown coal, then bituminous coal, and eventually hard, anthracite coal (coalification process).

As the coal is formed, the decomposing organic material produces methane gas, as well as nitrogen, carbon dioxide, and other gases. The burial process puts pressure on the coal, which keeps much of the gas in the coal.

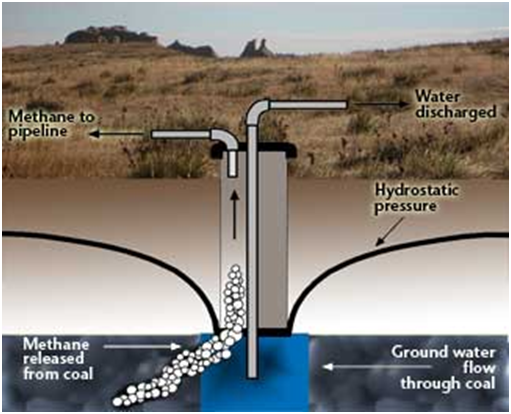

How Coal Bed Methane (CBM) is extracted?

CBM is extracted by drilling a well into a coal seam applying similar techniques used for other natural gas wells. The sides of the well are “cased” with cemented steel pipe. Usually, small holes, called perforations, are then made in the wall of the casing to let the CBM flow through into the well bore and up the casing to the surface. In some cases the wells are drilled horizontally and the coal seams are often stimulated or “fractured” to make the CBM flow more freely.

What are the prospects of Coal Bed Methane (CBM) in India?

India has the fifth largest proven coal reserves in the world and thus holds significant prospects for exploration and exploitation of CBM. The prognosticated CBM resources in the country are about 92 TCF (2600 BCM) in 12 states of India.

In order to harness CBM potential in the country, the Government of India formulated CBM policy in 1997 wherein CBM being Natural Gas is explored and exploited under the provisions of OIL Fields (Regulation & Development) Act 1948 (ORD Act 1948) and Petroleum & Natural Gas Rules 1959 (P&NG Rules 1959) administered by Ministry of Petroleum & Natural Gas (MOP&NG).

The Gondwana sediments of eastern India host the bulk of India’s coal reserves and all the current CBM producing blocks. The vast majority of the best prospective areas for CBM development are in eastern India, situated in Damodar Koel valley and Son valley.

CBM projects exist in Raniganj South, Raniganj East and Raniganj North areas in the Raniganj coalfield, the Parbatpur block in Jharia coalfield and the East and west Bokaro coalfields. Son valley includes the Sonhat North and Sohagpur East and West blocks.