What is Coal Gasification?

Coal gasification is the process of converting coal into synthesis gas (also called syngas), which is a mixture of hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and water vapour (H2O) . The syngas thus produced, can be used in a variety of applications such as in the production of electricity and making chemical products, such as fertilizers.

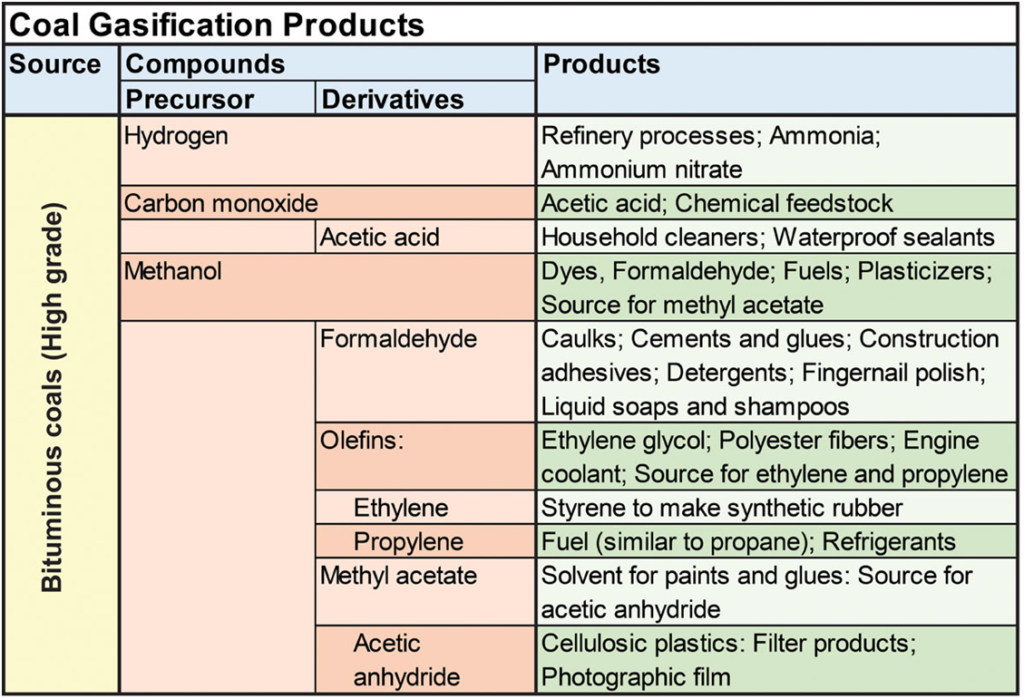

What are the Uses and Products of Coal Gasification?

֎ Large-scale coal gasification installations are primarily for electricity generation or for production of chemical feedstocks.

֎ The hydrogen obtained from coal gasification can be used for various purposes such as making ammonia, powering a hydrogen economy, or upgrading fossil fuels.

֎ Alternatively, coal-derived syngas can be converted into transportation fuels such as gasoline and diesel through additional treatment, or into methanol which itself can be used as transportation fuel or fuel additive, or which can be converted into gasoline.

֎ Natural gas from coal gasification can be cooled until it liquifies for use as a fuel in the transport sector. Coal gasification may be phased out in order to get to net zero greenhouse gas emissions.

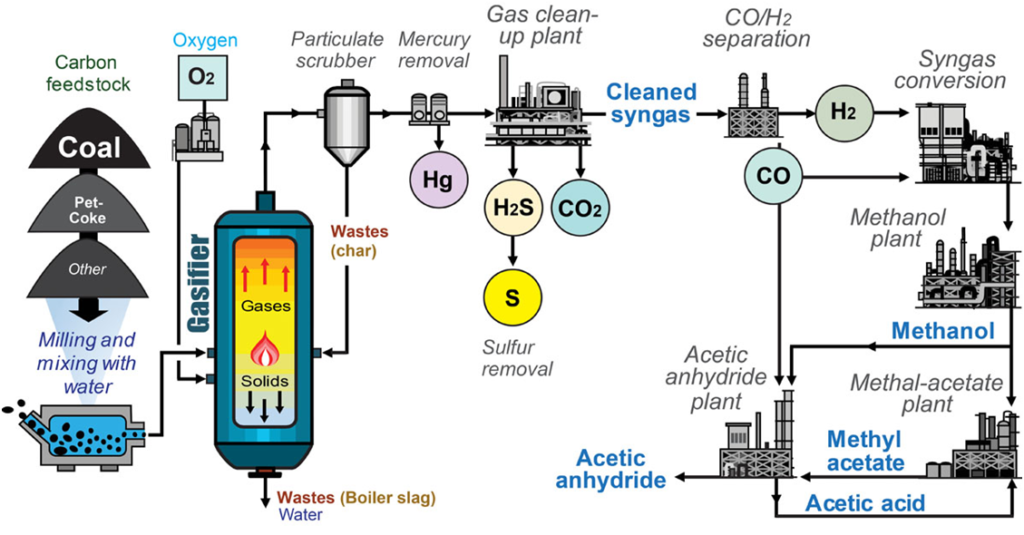

Process of Coal Gasification

During gasification, the coal is blown through with oxygen and steam (water vapor) while also being heated (and in some cases pressurized).

During the reactions mentioned, oxygen and water molecules oxidize the coal and produce a gaseous mixture of carbon dioxide (CO2), carbon monoxide (CO), water vapour (H2O), and molecular hydrogen (H2).

This process has been conducted in-situ within natural coal seams (referred to as underground coal gasification) and in coal refineries.

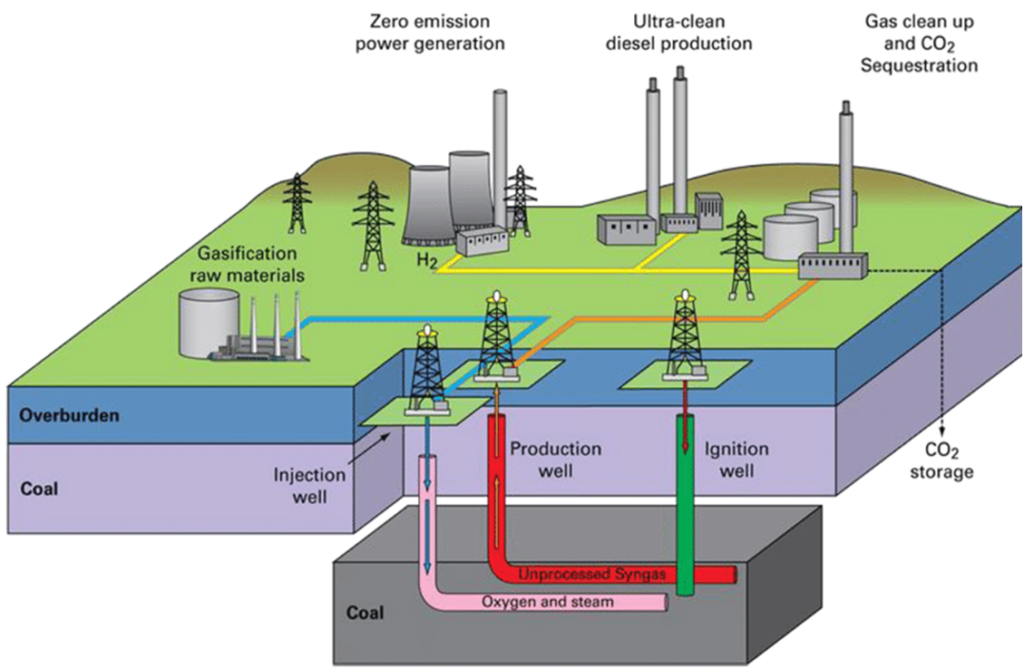

What is Underground Coal Gasification?

Underground coal gasification (UCG) is an industrial gasification process, which is carried out in non-mined coal seams. It involves injection of a gaseous oxidizing agent, usually oxygen or air, and bringing the resulting product gas to the surface through production wells drilled from the surface.

The product gas can be used as a chemical feedstock or as fuel for power generation. The technique can be applied to resources that are otherwise not economical to extract. It also offers an alternative to conventional coal mining methods.

Compared to traditional coal mining and gasification, UCG has less environmental and social impact, though environmental concerns exist, including the potential for aquifer contamination.

Why Coal Gasification is regarded as a cleaner coal technology?

There is no scrubber sludge produced by coal gasification plants thus there is no need of careful and expensive disposal. The majority of the wash water is reprocessed, and residual waste waters from gasification plants can be treated effectively. As a result, coal gasification is regarded as a cleaner coal technology when compared to coal combustion.

Why Coal Gasification is necessary for India?

֎ It is evident that India has huge reserves of coal, it would be beneficial for India if it finds a sustainable way of using these reserves as the world including India is gradually transitioning away from coal toward cleaner fuels in the wake of climate change.

֎ The use of domestic coal reserves becomes even more important, especially when India does not have other sources of fuel – crude oil and natural gas, 82% and 45% of the requirement of those fuels is met through imports. This exposes India to the vagaries of price volatility and supply insecurity.

֎ India will continue to depend on coal for its future energy needs at least till 2050 as per several reports.

֎ Since coal has to be used for coming 2 to 3 decades, there is an urgent need to make use of coal as green as possible.

China – A leader in Coal Gasification

Role of Coal Gasification in Methanol Production in China:

China has become by far the largest producing country in the world, representing 54% of world methanol capacity and 48% of world methanol production.

Around 70% of China’s methanol is produced from coal. China has significantly Increased Methanol Blending in fuels over the last few years.

Role of Coal Gasification in Ammonia/Urea Production in China:

China produces more than 90% of its ammonia through coal gasification. Ammonia capacity is approx. 30% of the world and urea capacity is approx. 40% of the world.

Role of Coal Gasification in Ethylene Glycol (EG) Production in China:

Capacity of coal-based EG is approx. 30% of China’s total.

Role of Coal Gasification in Methanol to Olefin (MTO) Production in China:

Capacity of coal-based Olefin is approx. 25% of China’s total.

What are the Advantages of Coal Gasification?

֎ Low Carbon Emissions.

֎ Sustainable, gainful & maximum utilization of national coal reserves.

֎ CO2 and other polluting gases can be separated, captured in cheaper way and utilized for other industrial uses.

֎ Strategic importance due to abundant availability of indigenous coal resource.

֎ Reduce dependence on imported energy sources, chemicals and feedstock for a variety of products.

֎ Widespread implementation & promotion of technology can make India “Atmanirbhar” in several value-added products.

֎ Mega coal to chemicals plant complexes at coal pit-heads can bring in regional economic prosperity as well as help meeting the gaps in interior states of the country.

Key Challenges in Coal Gasification in India

Coal Related

֎ Low Grade, high ash coal.

֎ Inadequate coal beneficaiton facilities.

֎ Quantity of fines due to improper mining.

֎ Variation in quality due to unavailability of dedicated source.

Technology Related

֎ Availability of proven gasification technology suitable for Indian poor-quality Coal.

֎ Costly & Complex coal feed preparation technology.

֎ High technology cost affects Syngas & downstream products costs & Project viability.

֎ Costly large capacity Cryogenic ASU plants required for Oxygen gas supply.

֎ Lack of experienced EPC / LSTK and O&M Manpower contractor.

֎ Due to demand / price fluctuations, only poly-generation route configuration is viable.

Environment Related

֎ Huge quantity of waste, black water generation.

֎ Costly waste treatment for ZLD.

֎ Costly systems for CO2, H2S removal.

֎ Ash storage and disposal.

Measures for encouragement of Coal Gasification in India

֎ Coal gasification to be recognised as “New Business Opportunity”.

֎ Recognition of coal gasification as Infrastructure sector.

֎ Modification in ‘Coal Distribution Policy’ to accommodate Coal Gasification including Producer Gas Plants using coal.

֎ Declaration of a separate sector to facilitate allocation of coal.

֎ Earmarking coal sources/blocks to supply right quality of coal.

֎ Fixation of Norms by a scientific institute for coal allocation to accommodate support units and considering type of gasifier, washability characteristics of coal, coal specifications & grade.

National Coal Gasification Mission

Government has launched National Coal Gasification Mission to achieve coal gasification and liquefaction of 100 MT of coal by 2030.

Suggested Key Initiatives by the Govt to make Coal Gasification a Success

֎ ‘Dedicated, closeby Coal Mines’ to be earmarked for Coal Gasification Projects (to be awarded through Auction Linkage) for better Coal Quality consistency , sustained Supply & closer Mining & Transportation Cost control.

֎ Viability gap funding, Infrastructure status Financial Incentives from Govt to support very high Capex of Gasification Projects needed to improve Viability of ‘Energy Security’ (Clean) Projects.

֎ Level playing field Exemption from currently applicable Cess / Duties on Coal Feedstock prices to be provided for Environment – friendly Coal Gasification Projects due to its Clean Technology adaptation.

֎ ‘National Policy on Coal Gasification & Liquefaction’ should be urgently formulated and promulgated for faster and smooth implementation of Coal Gasification based Projects.

֎ Schemes for ‘Blending Methanol, DME with Gasoline & LPG’ respectively to be implemented at the earliest. Policy framework for all by products of coal gasification.

PRACTICE QUESTIONS

QUES . Consider the following substances: UPSC PRELIMS 2025

I. Ethanol

II. Nitroglycerine

III. Urea

Coal gasification technology can be used in the production of how many of them?

(a) Only one

(b) Only two

(c) All the three

(d) None

Answer – (b) EXPLANATION: Nitroglycerin is not produced during coal gasification.Coal gasification technology can be used in the production of energy fuel (methanol & ethanol) and urea.